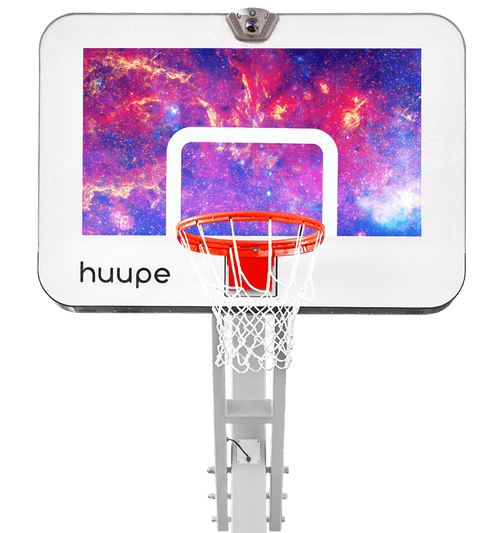

huupe PRO indoor

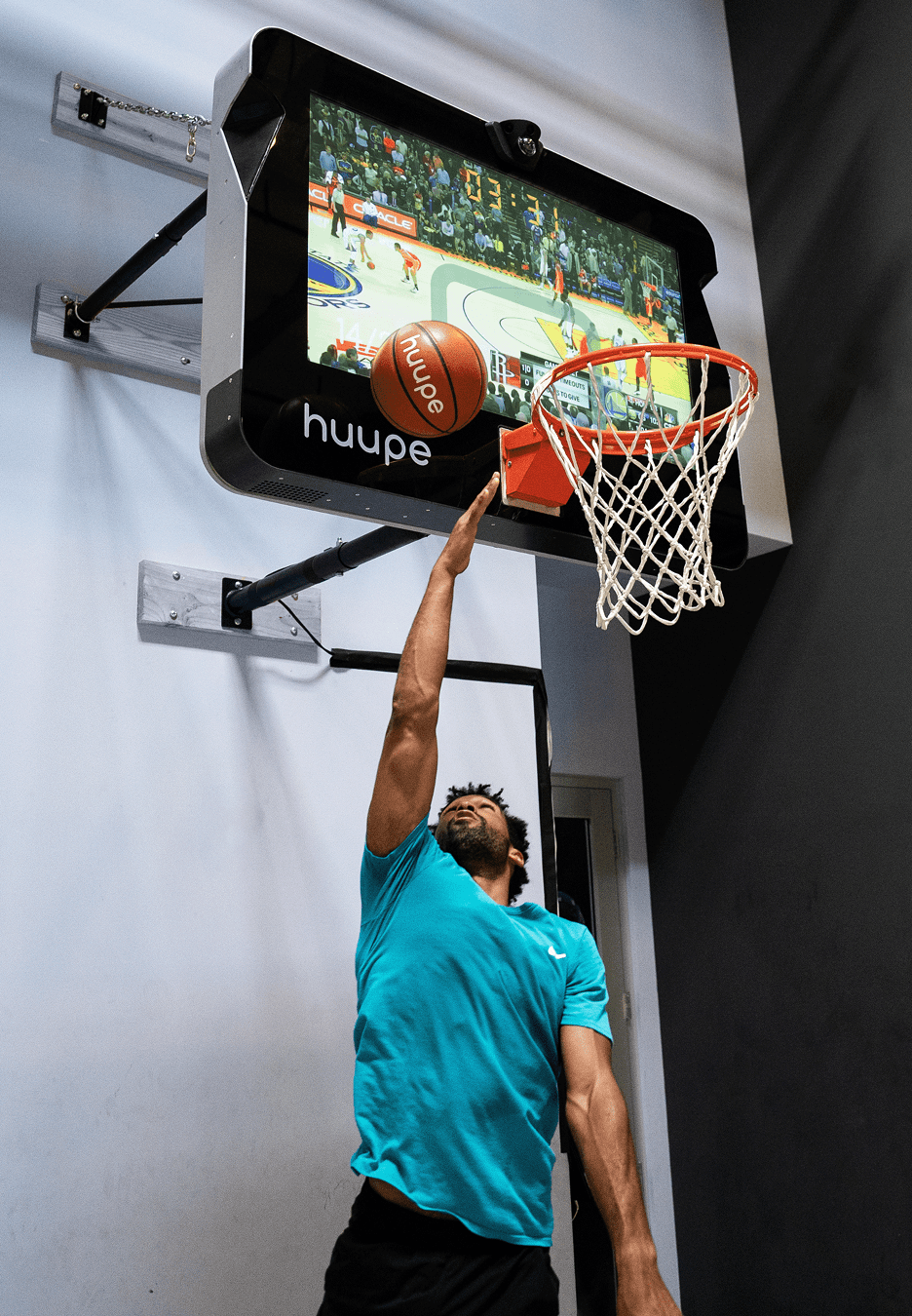

A full-sized regulation basketball hoop. The huupe PRO is the world’s first smart basketball hoop, with a screen for a backboard, that allows you to train like a pro, track your performance and play against other huupe users around the world in real-time challenges, with worldwide leaderboards and the ability to stream your favorite highlights and videos while you play and track stats.

Show More Show More Warranty Guaranteed

Warranty Guaranteed

Built to last. Dunk, shoot, play. Built for intense gameplay at every level

Built to last. Dunk, shoot, play. Built for intense gameplay at every level

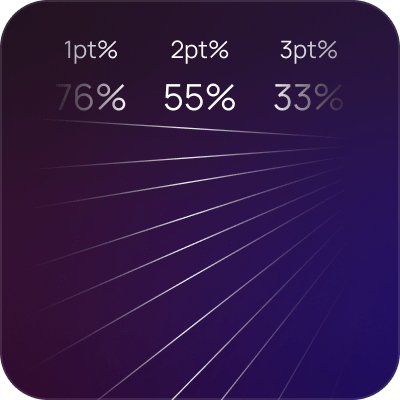

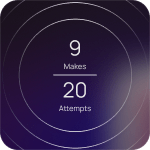

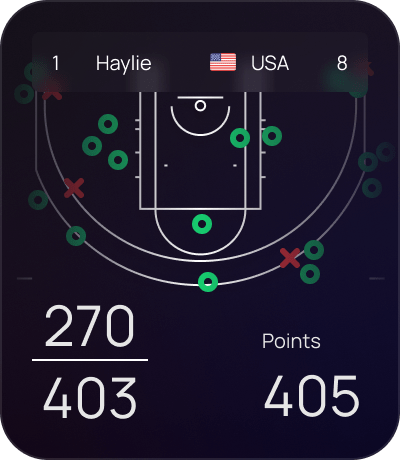

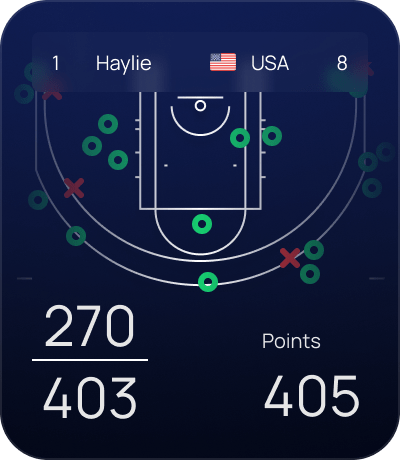

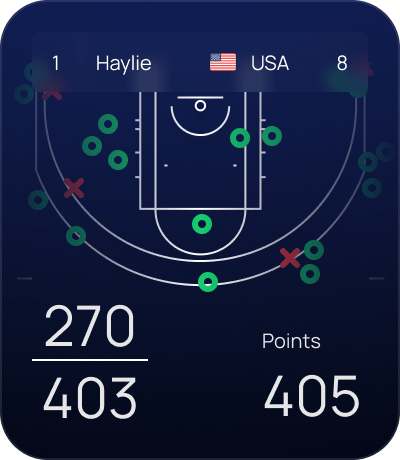

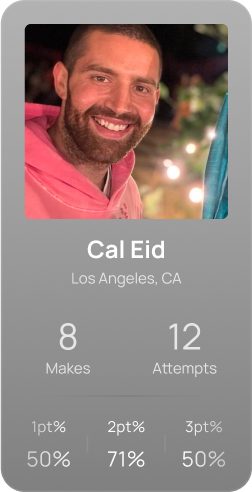

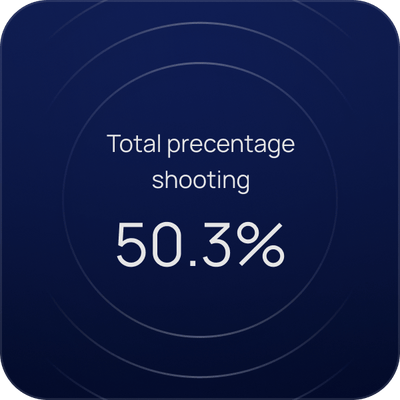

Tracks all stats on the court with 99.99% accuracy and real-time stats

Tracks all stats on the court with 99.99% accuracy and real-time stats

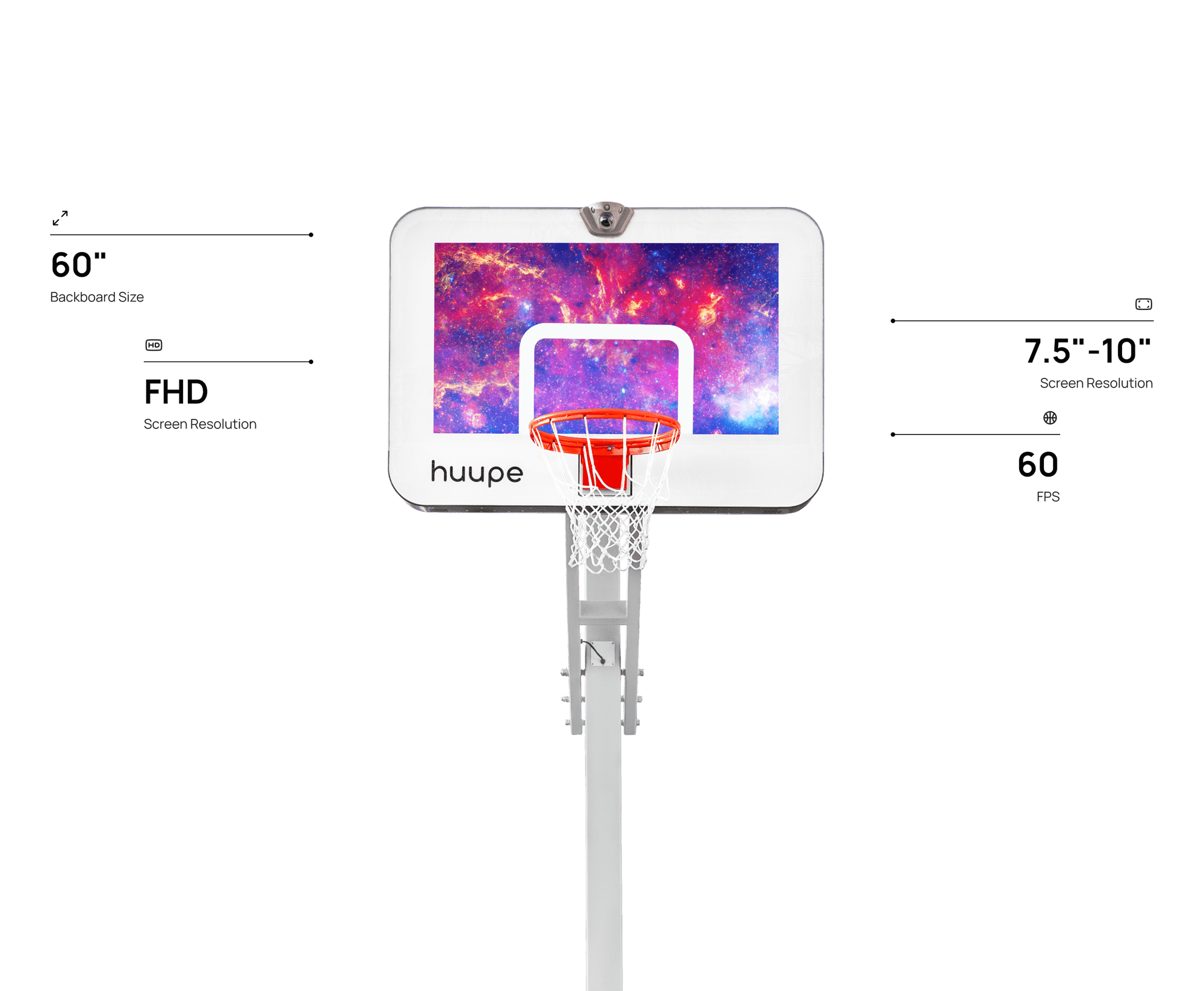

Experience crystal-clear visuals with a Full HD backboard display

Experience crystal-clear visuals with a Full HD backboard display

Durable design engineered to withstand intense gameplay

Durable design engineered to withstand intense gameplay

The World's First Smart Basketball Hoop

Take your training to the next level with professional trainers and real-time analytics feedback that only the pros get.

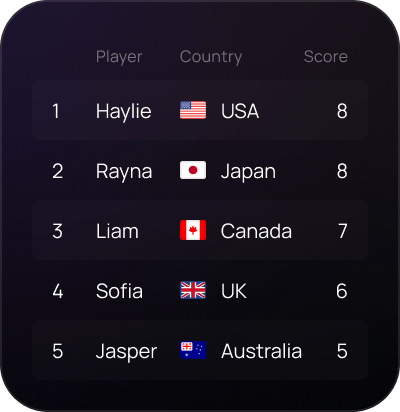

Join a Community of Legends

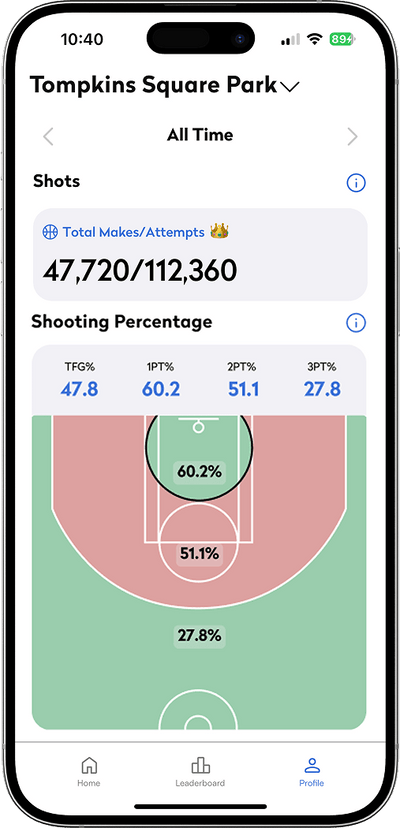

Easy to use mobile app

Stream our mobile app right to the huupe and play.

World Class Engineering, Next Level Performance

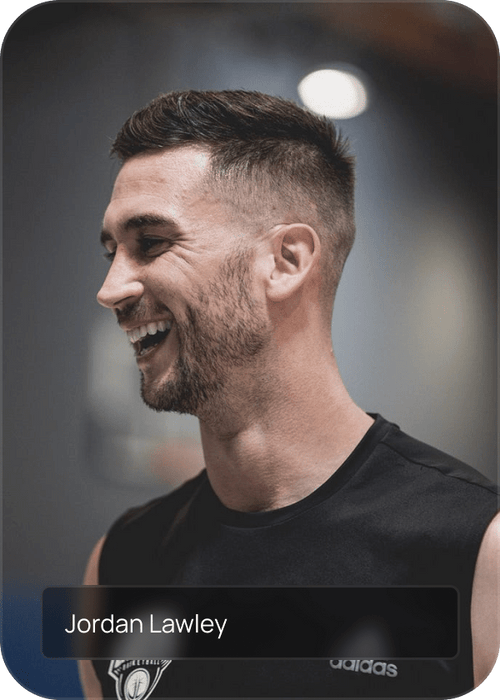

Our trainers

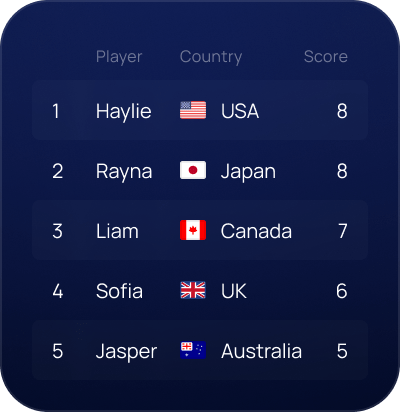

Play Against Friends Around the 🌎 World

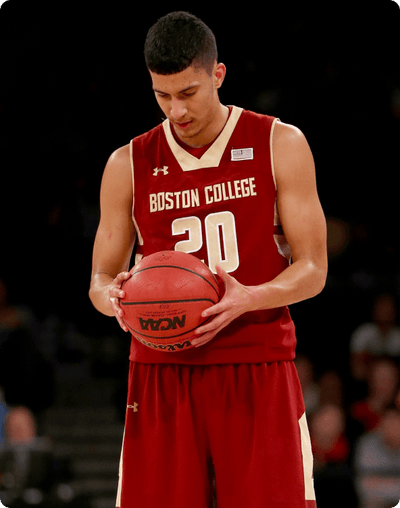

Why NBA, WNBA and College Athletes love the huupe PRO

Customer Reviews

huupe PRO Installation

Frequently Asked Questions

Need some support or have questions about huupe?

Here are our most frequently asked questions.

Need some support or have questions about huupe? Here are our most frequently asked questions.

If you order today, your huupe PRO can arrive as soon as 1-2 weeks from order. We're currently in stock on the huupe PRO indoor units. Limited amount left. Order today before we sell out!

If you're looking to buy a basketball hoop to replace your existing one, then the professional installers that install your huupe will remove your current hoop and replace it with a huupe!

Yes, the huupe PRO will be available for purchase in Hawaii and Alaska.

Once your order has been confirmed you will receive a pre-installation survey via email to confirm the placement of your huupe.

For an optimal huupe experience, we recommend at least a half court to play on for the huupe PRO, which is typically 50' baseline by 42' sideline.

The smallest half court we've installed on is 16' x 20' ft.

This decision is up to you. You do not need a full half court! Just enough room to play basketball as you like.

For your safety, it is important that the huupe is installed by professional installers.

In addition to delivering and installing the huupe in your home or driveway, the professional installers will connect the huupe to WiFi, pair your Bluetooth, and get your account set up so you can start training right away.

Yes, the huupe PRO works with any ball.

We recommend orange basketballs as those work best, 99.99% accurate in optimal lighting conditions.

Optimal lighting conditions are clearly lit courts and places.

If it is too dark outside, the huupe PRO can physically not see the ball as well and shot tracking will be compromised.

The huupe PRO comes all included with the backboard, rim, net, and pole or wall-mount based on what you select for install.

It comes fully equipped with everything you need to have it set up and play.

No, there is no mandatory subscription for the huupe PRO.

Every core feature is free to use and play.

There will be an elevated membership subscription for those who want added content, the ability to advertise on the backboard and more.

The huupe PRO is controlled by our mobile app.

You simply connect your mobile app via bluetooth to the huupe PRO, then in our mobile app you connect the huupe PRO to Wi-Fi, and you're all set and will have full control of your huupe PRO!

The huupe PRO can be installed in-ground or in the wall.

We have installation videos here if you would like to see this process.

For your safety, it is important that the huupe is installed by professional installers.

In addition to delivering and installing the huupe in your home or driveway, the installers will connect the huupe to WiFi, pair your Bluetooth, and get your account set up so you can start training right away.

ronnie2k

ronnie2k